Digitization has had a profound impact on various industries, transforming their operations and enabling them to gain an edge in this competitive world. In the manufacturing industry, implementing digital technology can improve all aspects of the manufacturing process. Today, many organizations rely on back office outsourcing services to accelerate their digitization efforts. BPO providers often leverage advanced technologies, such as robotic process automation (RPA), artificial intelligence (AI), and data analytics, to modernize back office operations and enhance productivity. Applying these technologies to digitization initiatives, such as data digitization, data entry automation, and document processing, can accelerate the digitization process and improve accuracy and efficiency.

Surveys reveal that there is an increased interest in digitization and adoption of new technologies among manufacturers. Data from Fictiv’s 2022 State of Manufacturing Report shows that most of the industry leaders surveyed are using or implementing digital manufacturing tech to improve manufacturing and supply chain visibility, enhance the customer experience and satisfaction, and increase operational efficiency for new product development (www.forbes.com).

What is Digital Transformation in Manufacturing?

Smart manufacturing refers to the use of digital technologies to transform the manufacturing value chain. Digital transformation in manufacturing involves applying digital technologies, data, and automation to transform traditional manufacturing operations, processes, and business models.

It involves the incorporation of digital technologies and advanced software across all areas of manufacturing:

- Product design

- Production

- Supply chain management

- Operating procedures

- Quality control

- Customer engagement

Digital transformation in manufacturing typically involves the adoption of technologies, such as:

- Industrial Internet of Things (IIoT): IIoT involves utilizing data from various industrial devices, sensors, and equipment for real-time monitoring, data analysis, and process optimization. IIoT can provide valuable insights into production processes, machine performance, energy consumption, and other operational aspects, enabling manufacturers to make data-driven decisions and optimize operations.

- Big data and analytics: Big data and analytics technologies and document digitization services enable manufacturers to process and analyze large volumes of information to gain insights, identify patterns, and optimize processes.

- Artificial Intelligence (AI) and Machine Learning (ML): AI and ML technologies can be used in manufacturing for predictive maintenance, quality control, demand forecasting, and supply chain optimization.

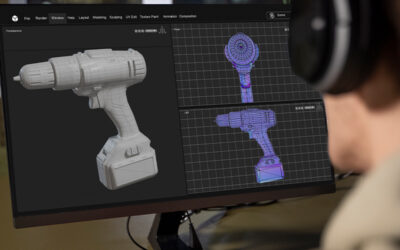

- 3D printing: Also referred to as additive manufacturing, 3D printing is a digital technology that allows manufacturers to produce parts or components layer by layer, based on digital designs, which can accelerate product development and reduce time to market.

- Cloud computing: Cloud computing allows manufacturers to store, manage, and process data and applications in the cloud, enabling access from anywhere and driving collaboration.

Digital transformation in manufacturing can bring numerous benefits, including improved operational efficiency, increased agility, improved product quality, faster time to market, optimized supply chain, reduced costs, and new business opportunities. Let’s dive into these benefits in greater detail.

7 Ways Digitization Benefits the Manufacturing Industry

Here are 7 ways cutting-edge information technologies impact the manufacturing business:

- Increases efficiency: By automating repetitive tasks, reducing manual errors, and streamlining workflows, digitization has significantly improved efficiency in the manufacturing industry. Digital tools and technologies enable manufacturers to optimize their operations, reduce costs, and improve productivity.

- Enables designing and developing products faster: The process of digitization allows for the rapid development and introduction of new products, product enhancements, extensions, variations, or even customizations, leading to faster and easier innovation. This can significantly accelerate business growth by enabling manufacturers to quickly adapt to changing market demands and customer preferences and bring new offerings to market with greater speed and efficiency.

- Leverage data real-time to accelerate business growth: The IIoT provides access to a wealth of information and tools that are essential for employees to perform their jobs effectively. It connects all processes on the shop floor and delivers paperless work instructions, engineering drawings, and inspection sheets directly to operators. With instant access to the information they need to carry out their tasks, operators can minimize time wasted searching for data or trying to understand what’s happening. With real-time visibility into operations, they can quickly identify root causes of issues and take appropriate actions, resulting in improved productivity and operational efficiency.

- Supports RMA reporting: Digitization plays a crucial role in supporting RMA (Return Merchandise Authorization) reporting in manufacturing. RMA Reporting and Product Tracker apps enable manufacturers to efficiently document and analyze returns or product recalls from customers or suppliers. These apps capture essential information about returned products, including the reason for return, quantity, condition, and disposition (e.g., repair, replacement, refund, and disposal). By providing valuable insights into product quality, customer satisfaction, and areas for improvement in manufacturing processes, RMA reporting enables manufacturers to track and analyze product returns, identify patterns or trends, and take appropriate corrective actions to prevent recurrence and enhance product quality. Digitization streamlines the RMA reporting process in manufacturing, and makes it more efficient and accurate, leading to better decision-making and improved customer satisfaction.

- Enhanced communication and collaboration: Digitization has revolutionized communication and collaboration. Digital platforms, such as email, messaging apps, and project management tools, have made it easier for employees to collaborate remotely and share information in real-time, resulting in increased productivity and faster decision-making in the manufacturing industry.

- Enables predictive maintenance: Digitization enables the collection, analysis, and utilization of data to support predictive maintenance in manufacturing. By leveraging real-time data, advanced analytics, and automation, digitization supports hands-on maintenance, minimizes unplanned downtime, optimizes resources, and improves overall equipment reliability and productivity.

- Reduces waste: Waste, in its various forms, poses significant challenges to manufacturing operations. However, smart manufacturing can play a pivotal role in driving business growth by effectively reducing waste. Whether it’s material waste, energy waste, labor waste, or production time waste, digitization allows manufacturers to leverage data-driven insights and automation to identify, track, analyze, and eliminate the root causes of waste. By addressing waste at its source, smart manufacturing prevents the loss of valuable resources, such as materials, labor, time, and energy. It optimizes manufacturing processes, improves efficiency, lowers costs, and drives sustainable manufacturing practices.

Businesses that placed a strong emphasis on digitalization during the COVID-19 pandemic have demonstrated greater resilience in 2021-2022. Digitalization enabled them to adapt to remote work, maintain digital communication and collaboration, leverage e-commerce and online services, make data-driven decisions, optimize processes, and build resilient supply chains. These digital capabilities have helped them navigate the challenges posed by the pandemic.

Careful planning, investment in technology, skilled manpower and infrastructure, and organizational change management is essential to effectively leverage the potential of digital technologies and drive successful digital transformation initiatives in the manufacturing sector. Partnering with a Robotic Process Automation Company can drive digital transformation by automating manual and repetitive tasks, enhancing data accuracy and data quality, and facilitating process optimization.

Say goodbye to manual and paper-based processes! Call us today to discuss how we can support your digitization initiatives and drive success for your business!

Call us @ 1-800-670-2809 and get your Free Trial today!