Today, the needs and expectations of customers have changed drastically. They prefer high quality products, value-added services and quick delivery. This has increased the need for digital transformation ranging from 3D printing of dresses to smart factories. However, the process of digital transformation is not an easy one. It requires a proper digitization strategy.

What are the important things to consider?

- Have a proper planning and clear mission: The first and foremost thing is to have a clear mission with specific goals. Consider the scope and volume of digital transition such as changes to structural and decorative design processes, legacy system updates, supply chain partnership and all other important factors. A good example is that of Pacific Textiles, a $900 million manufacturer of customized knitted fabrics in Asia that wanted to streamline operations, expand internationally and become an industry frontrunner in Industry 4.0. A well-focused and end-to-end operational audit helped them in a smooth digital transition. They could implement a platform that could support real-time data analytics and achieve transparent ERP management. Digitization allows greater manufacturing integration and intelligence which in turn enables quick automation and greater transparency.

- Data are assets: The textile industry generates huge volumes of data and forward-thinking companies must view data as a priceless commodity. If data is not utilized properly, it could lead to ineffective sourcing processes, limited supply chain visibility, disconnected financial systems, and poor sustainability management among other issues. So, data cannot be ignored. It is important for competitive advantage. Optimal use of these data helps companies to gain market control and to establish themselves as digital leaders.

- Executives must promote change: In the next few years there will be more and more investments in data monitoring tools and it will help businesses to judge customer demand and deliver value-added features in the products, boost customer relationship, and also build brand loyalty. However, these changes cannot occur if top level executives do not provide the necessary support. Many organizations face the problem of “do not change what’s working” attitude. The most important element for successful digital transformation is the support of senior executives and they should be role models for the organization to adopt an innovative system.

- Product standardization may not be the answer: Textiles come in a number of variations. Product standardization has been the go to strategy for companies to maintain profits. But this approach does not always provide the desired results. Organizations should now focus on value from the data generated by the millions of individual transactions. The information gained from these transactions can be used to facilitate order completion through customized solutions. Market players should adopt a customer centric approach and digital technology is crucial to support complex data processing.

Lectra — an Example of Successful Digitization

Holger Max-Lang, the new Managing Director of Lectra Germany since January 2018 says that the new technology has revolutionized the clothing industry. He has been working for more than 15 years at the technology provider from France, which is now automating and optimizing the entire value-added chain – from design and development to manufacturing with the support of industry-specific hardware and software solutions using Industry 4.0 solutions. Since 2013, Lectra has invested 86 million Euros (9.4% of turnover) in research and development.

- According to Max-Lang, Lectra is moving towards mobile production lines. Container solutions can be integrated into a pop-up store – individual production for local sales with the help of automation and robotics. Nanotechnology and the textile industry are increasingly being integrated, resulting in smart textiles or intelligent fabrics created with woven-in electrical engineering.

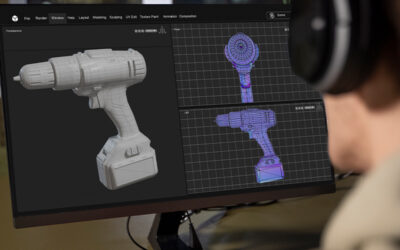

- Another application of digital technology is 3D simulation that helps save time and money. The 3D design is based on simulated 2D pattern pieces. You don’t have to try on patterns developed by the designer by hand. Prototypes are no longer required with the 3D simulation. This enables time and money savings, and is a major step towards the digital development process. Lectra’s 3D solution Modaris is used by companies for women’s wear as well as men’s wear because the system offers a pool of pre-fabricated cuts.

- There is enormous potential for automation and digitization on the one hand, and for linking processes and data streams on the other. However, mankind as a workforce will remain part of the textile value chain.

- A digitized network of production chain helps to connect departments with each other and this simplifies and facilitates product development and production hugely. Nearby production sites are becoming increasingly important. Manufacturers need to be responsive, cost-effective and customer-focused.

Digital transformation is the future, so eventually all industries will have to adopt this innovative trend. Digitization with the help of professional outsourced solutions helps to improve productivity, efficiency and achieve business objectives without wasting time and resources.